Engine control modules (ECM) are found in all modern vehicles. From the smallest economy car to the biggest diesel trucks, all have a computer that controls how the engine runs, managing everything the engine does. A properly operating diesel ECM will increase fuel economy and help the engine supply the power you need. The ECM controls everything from precise timing to delivering appropriate fuel to the injection system. It’s processing thousands of bits of data per second and then sending out signals to tell the engine what to do.

At GoECM, we specialize in remanufacturing diesel ECMs. These are OEM units that are removed from another vehicle and rebuilt using a complex detailed procedure.

Why Should You Buy a Remanufactured ECM?

There are a couple of reasons that you should choose a remanufactured ECM from GoECM:

- Better than OEM - A remanufactured ECM, at least from us, includes the latest technology. We utilize the newest and most advanced components and testing procedures. We have developed design improvements and tested modules with higher quality components that are often better than ones that originally came with your truck or equipment.

- Less Expensive - A remanufactured ECM from GoECM is less expensive than a new one. Save thousands of dollars and receive lifetime durability – guaranteed. We cut out the middlemen. We are the remanufacturer and distributor, all-in-one, in order to offer the savings straight to our consumers.

- Recycling – The remanufacturing process is a form of recycling. By remanufacturing the ECM, we are contributing to a cleaner environment and a more responsible use of our current resources.

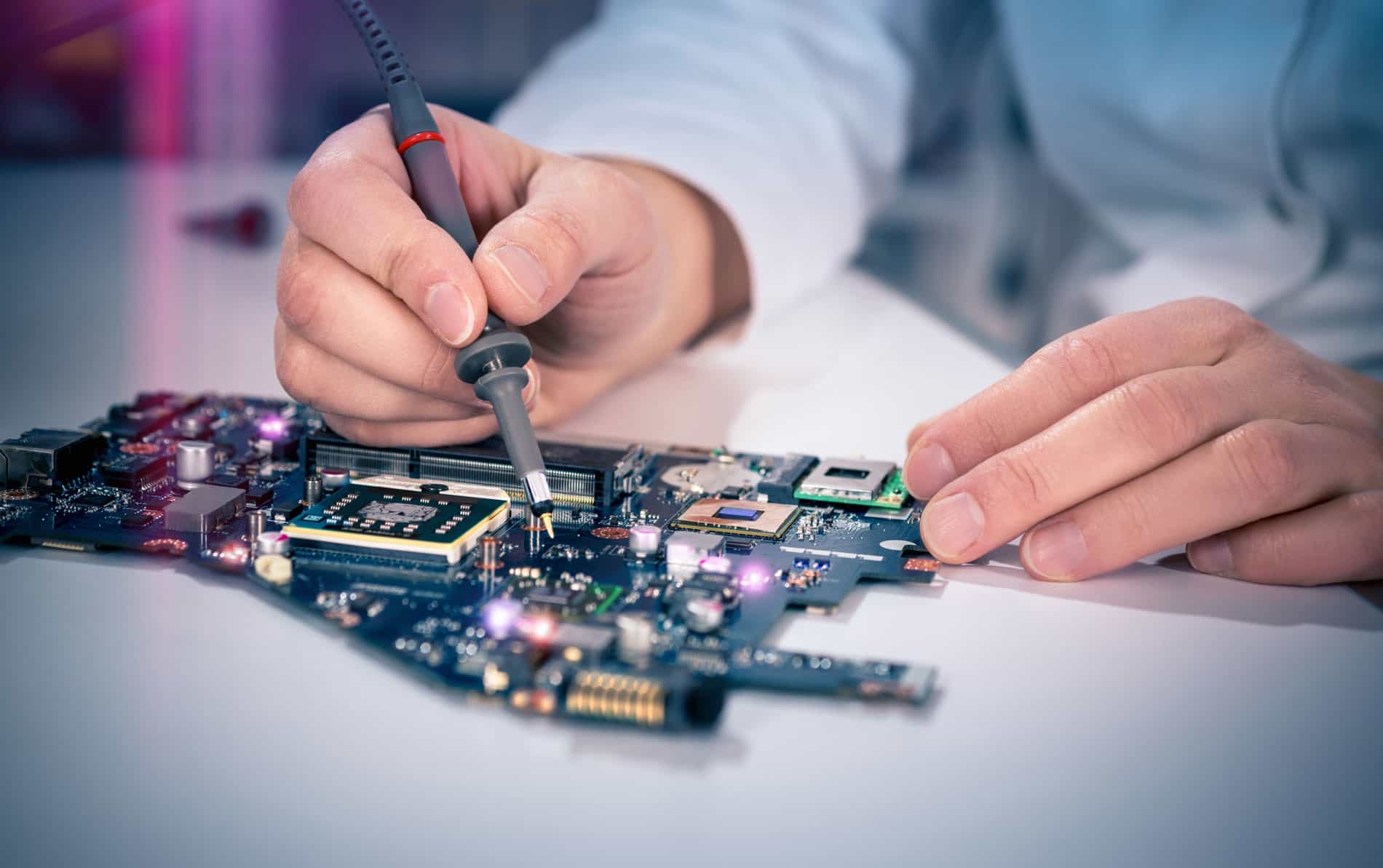

How do ECMs get Remanufactured?

Remanufacturing ECMs is a meticulous, specialty service. At GoECM, we’ve made a science of it. We specialize in Cummins ECM, Caterpillar ECM, International ECM, Detroit ECM, and many more. We also carry over 10,000 ECMs, each remanufactured and in a ready state for programming and calibrating purposes.

The Remanufacturing Process

At GoECM, we work hard to deliver the very best Diesel ECM solutions available on the market today. We evaluate, repair, assess and reprogram our remanufactured ECMs.

It’s a multi-step comprehensive process that you don’t see when you open the box of your ECM.

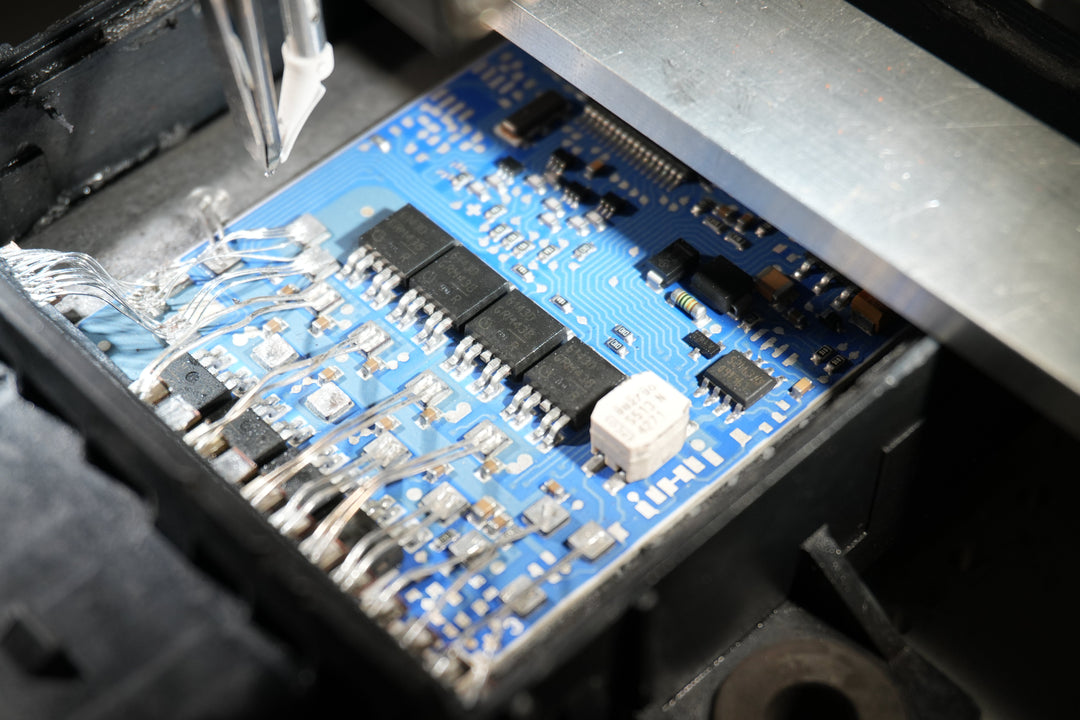

- Disassembly & Inspection - The core or failed ECM to be reclaimed is carefully disassembled. We initially disassemble and inspect visually throughout this process to ensure no physical damage or contamination has occurred. Each unit that is remanufactured must meet certain criteria for it to be accepted, repaired and sold.

- Component Level Testing - After the initial visual inspection, each ECM is tested at the component level. To test the hardware, we use the newest developments in technology to test circuits and microcontrollers. The software and hardware are assessed, and each step is documented using a check list that we provide with each module.

- The ECM Repair - Each module is individualized and remanufactured based on its condition once we receive the module, however each module goes through the same procedures regardless of the condition. With electronics, every component has a tolerance that is aged over time. The component might test according to factory specifications, but we want lifetime durability. To properly remanufacturer these modules you must understand the rigorous conditions the modules are subject to. Certain components are prone to failure due to several factors including internal conditions and abuse. Those components are replaced with brand new components with improved tolerances and superior operating functions.

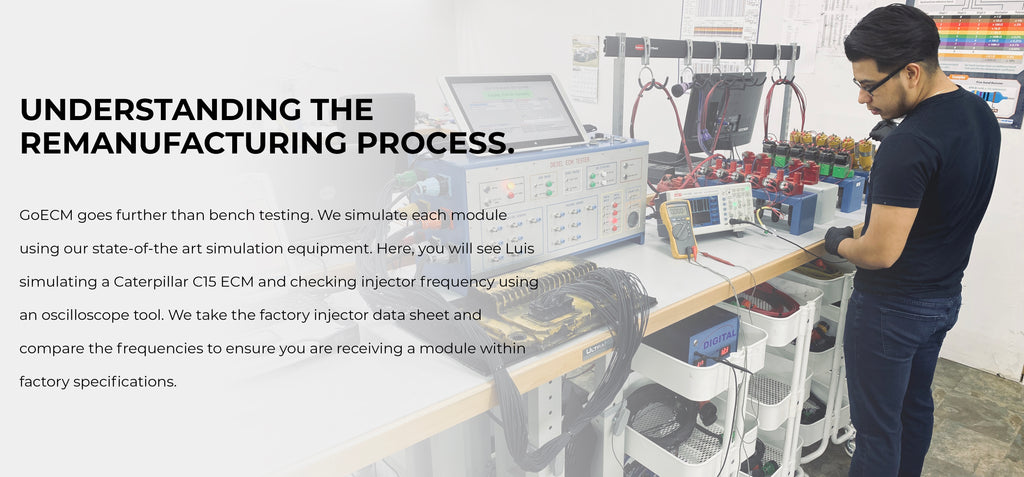

- Quality Testing - Final verification is determined after the repair using precise testing equipment. GoECM has spent years developing vehicle simulators that reproduce engine behavior. Our proprietary systems effectively assess all aspects of the control modules. We use load and temperature tests to simulate on-vehicle conditions. These tests run for several hours prior to approval.

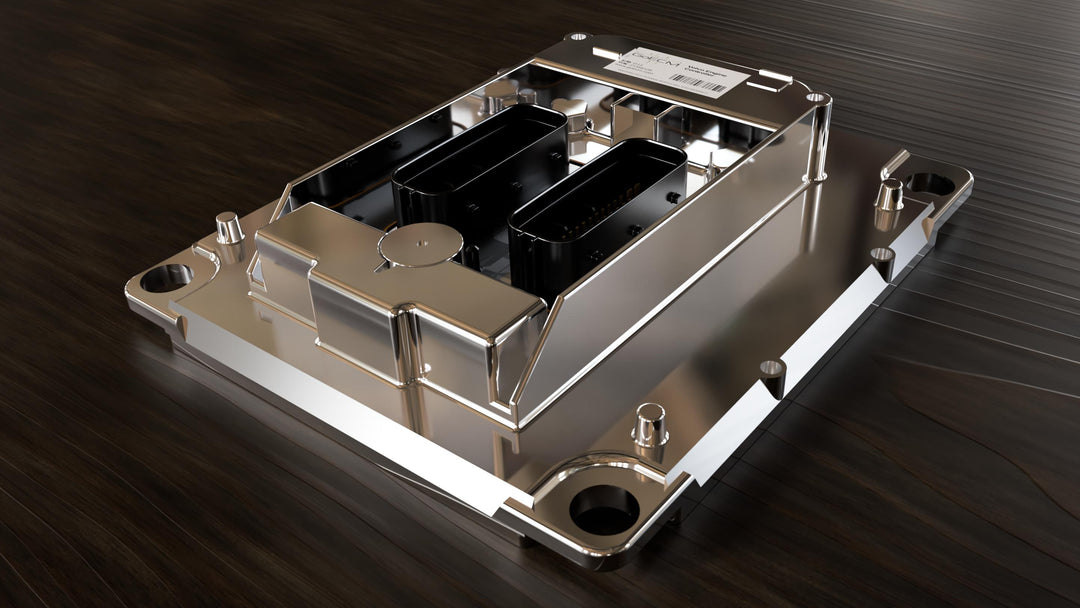

Replacing External Hardware

In some cases, we replace several external components of an ECM. Our complete audit of a Diesel ECM also includes cosmetic inspection. The housing is inspected for any cracks or dents. Mounting points are inspected and tested for durability. GoECM believes the physical condition of an ECM should reflect the internal excellence. We use new bolts, washers and spacers when necessary. We have also developed new housings and covers for several applications, so you receive a module that is as close to “new” that the industry has to offer.

What about Auto Parts Stores?

Many auto parts stores carry refurbished ECMs. In truth, they’re often buying from companies like GoECM. Come straight to the source and receive our industry leading customer service and lifetime guarantee.

Purchasing a Diesel ECM from GoECM allows us to guarantee that your receiving a high-quality remanufactured ECM, perfect for your vehicle. We fully back our products with lifetime warranties because we truly believe that we offer original performance with more potential in reliability and durability.

Don’t take chances with arguably the most important component of your engine. If you really want to get the most from your truck, get a remanufactured Diesel ECM that’s better than the one it came with.