The Merge of Volvo and Mack

The year 2009 marked a significant milestone in the trucking industry when Volvo Trucks North America and Mack trucks joined forces under their common parent - Swedens Volvo Group. This merger birthed “North American Trucks” (NAT), Helmed by Dennis Slagle, former President of Mack Trucks and Per Carlsson, the former President of Volvo Trucks North America. Despite this merger, the individuality of the two renowned truck brands, Mack and Volvo has been preserved.

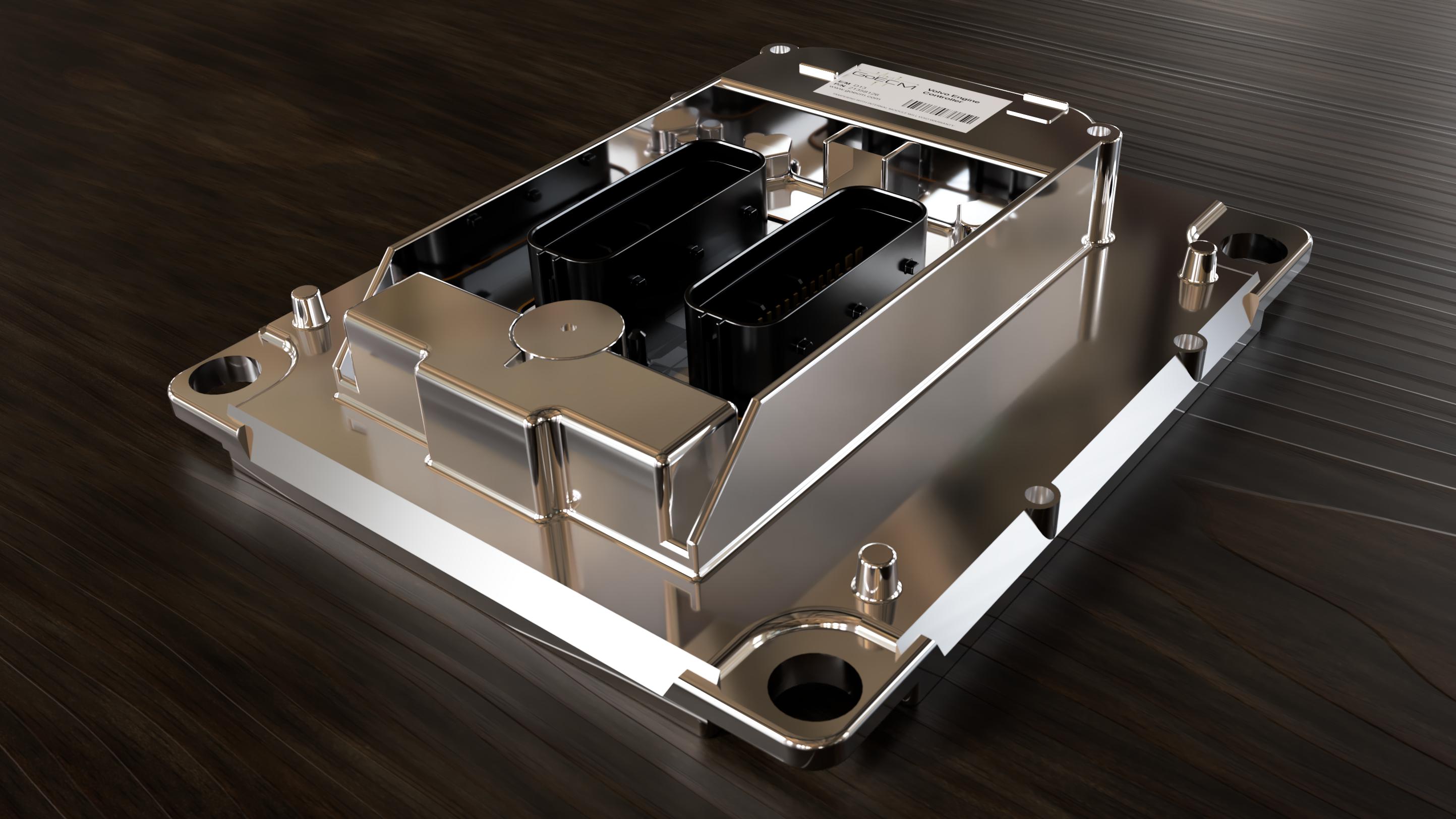

The Role of an ECM in Vehicle Performance and Efficiency

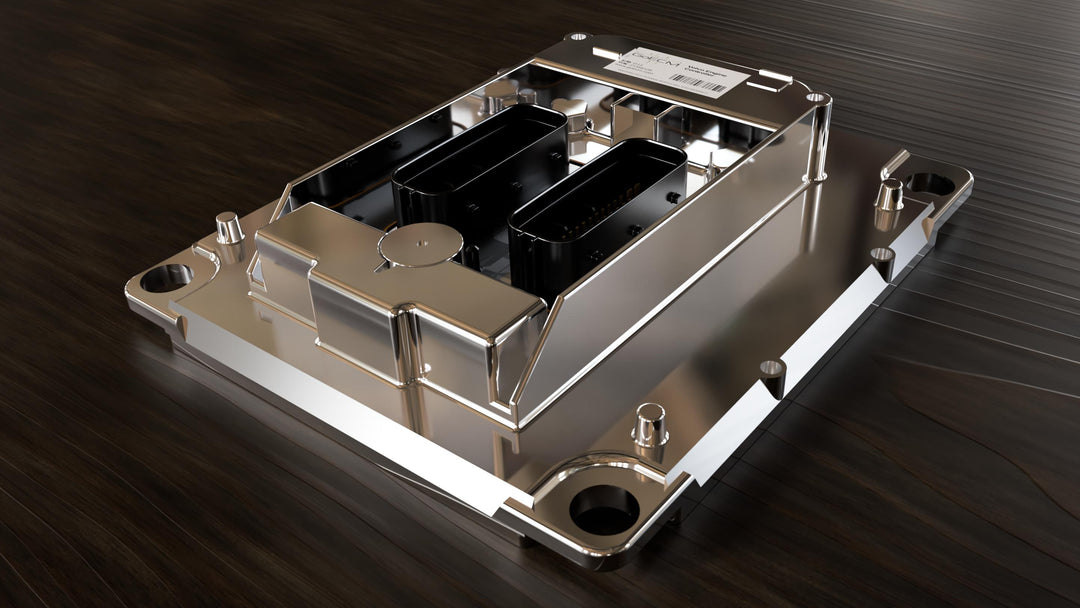

At the heart of every modern truck lies the engine control module (ECM). Often referred to as the vehicle's brain, the ECM is powered by the battery and holds the responsibility of regulating various engine functions. This essential component constantly monitors data from numerous sensors, making crucial adjustments to fuel supply, injection systems, engine timing and emissions. Furthermore, the ECM collaborates with other modules like the powertrain control module (PCM) and transmission control module (TCM), Which oversee shifting, anti-lock braking system and traction control.

What Causes ECMs to Fail? What are the Common Issues?

ECM failures manifest through a range of symptoms: illuminated engine lights, vehicle starting issues, misfires, decreased fuel efficiency, loss of acceleration, unexpected engine shutdowns, and irregular shifting. The root causes frequently trace back to corrosion in wiring harnesses and increased moisture levels. Aging vehicles, typically around 5 to 10 years, are susceptible to these issues due to prolonged exposure to the elements.

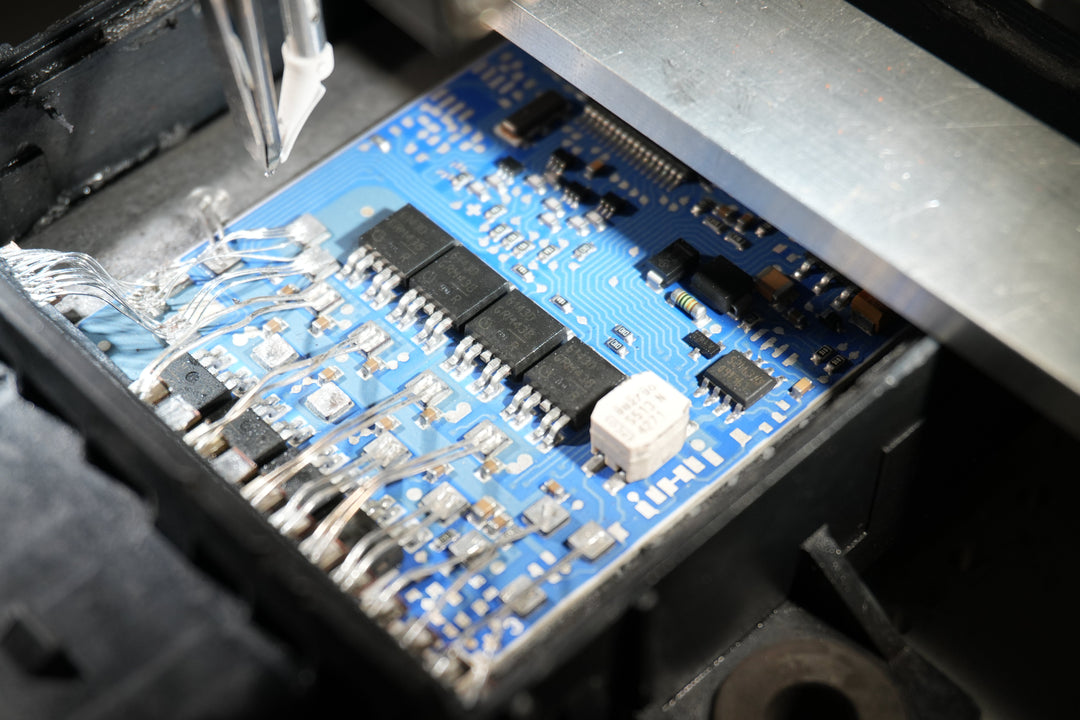

Moisture infiltration and corrosion results in shorts or electric surges, leading to erroneous readings and faulty codes. Oil damage weakens components over time, while water/moisture damage severity determines repair feasibility. One layer board damages can often be repaired, however the complexity of two or three layered boards usually necessitates replacement - especially for intricate components like memory or processor units.

Best Practices to Fix Mack ECMs and Volvo ECMs

In the context of Volvo or Mack trucks, ECM issues are frequently associated with component failure due to life expectancy. These components contain acidic substances, which can corrode the copper and circuit boards if not promptly addressed. Visual inspection and diagnostic programs are employed to identify faulty components. If repairable, damaged areas are meticulously cleaned and the components are replaced with higher-graded components to prevent future failure. Severe damage to the middle layer of a three layer ECM board often renders repair impossible, warranting ECM replacement. Another prevalent problem involves injector circuits. Faulty injectors can short into the ECM, but these issues are usually repairable. Prompt identification and replacement of malfunctioning injection prevent further ECM damage.

Additionally, instances of oil contamination demand meticulous cleaning and inspection. Depending on the extent of the damage, removal of oil and subsequent evaluation determine whether the ECM can be salvaged. Severe cases often necessitate ECM replacement to ensure optimal performance.

Understanding ECM functionalities and addressing issues promptly and effectively are crucial for maintaining the reliability of Volvo and Mack trucks. By recognizing common problems, their causes and employing best practices for repairs, truck operators can minimize downtime and enhance efficiency. Maintaining these practices will in turn will prolong the lifespan of their vehicles, ensuring smooth journeys on the road.